At the beginning of the project, we analyzed the two parts, working in co-design with the architect Sessa for the necessary adjustments to make the object printable.

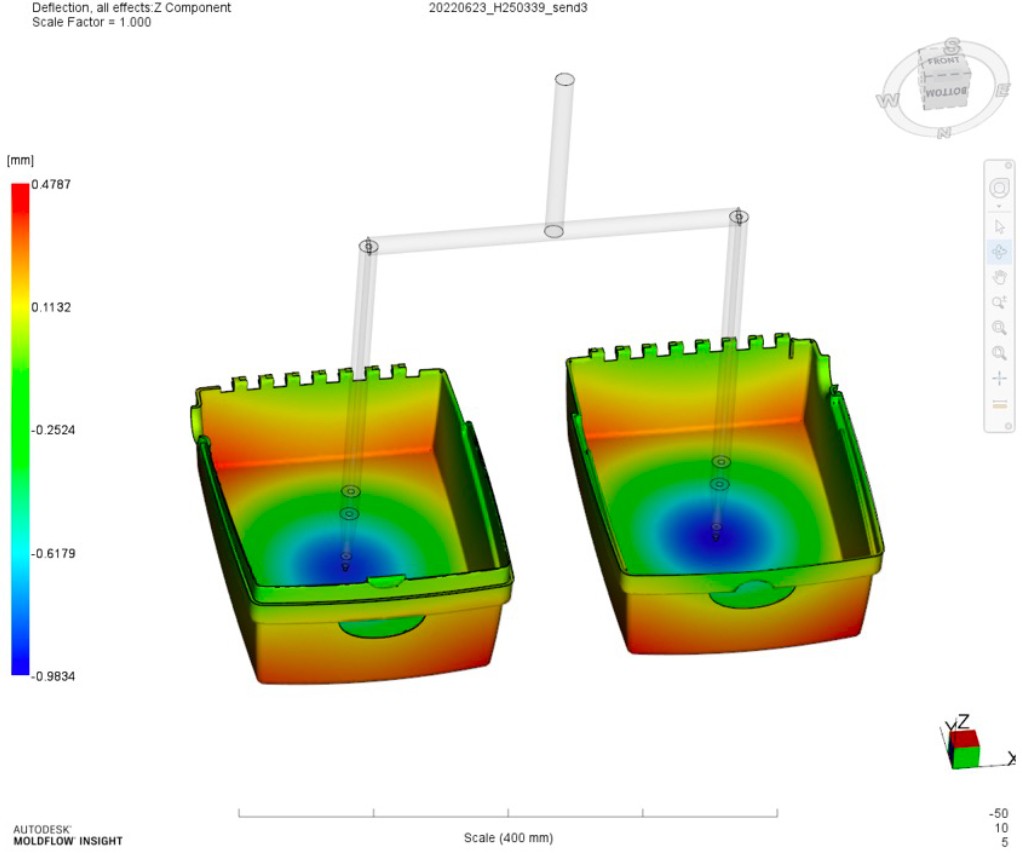

After the validation of the final models, we proceeded with the first phase of setting the mold and a draft on which to perform specific analyses: some Moldflow analyses were conducted, analysis necessary to test in advance the final operation of the production mold and the behavior of the material inside the two cavities.

Once we certified the good filling and the absence of distortions of the post-molding object, we moved on to the final stage of mold design.

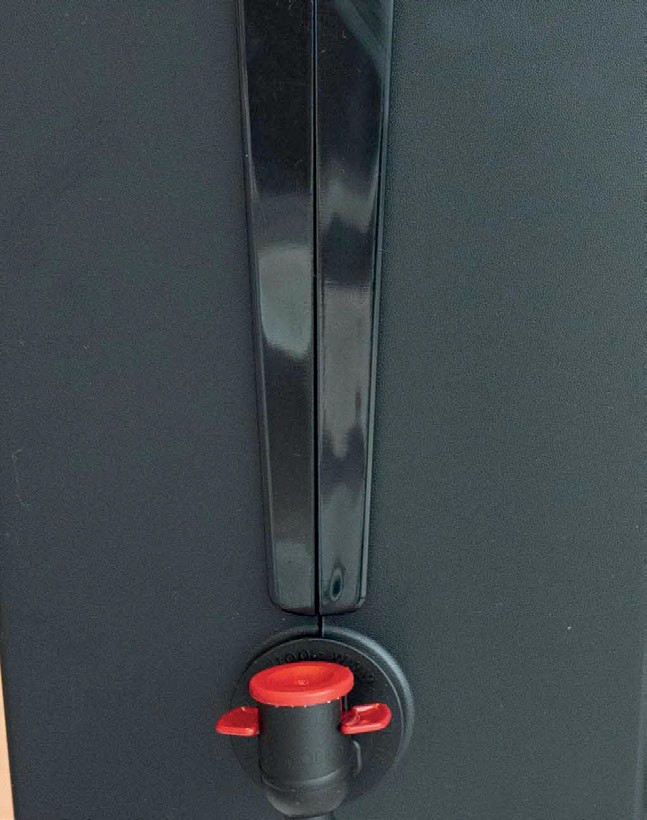

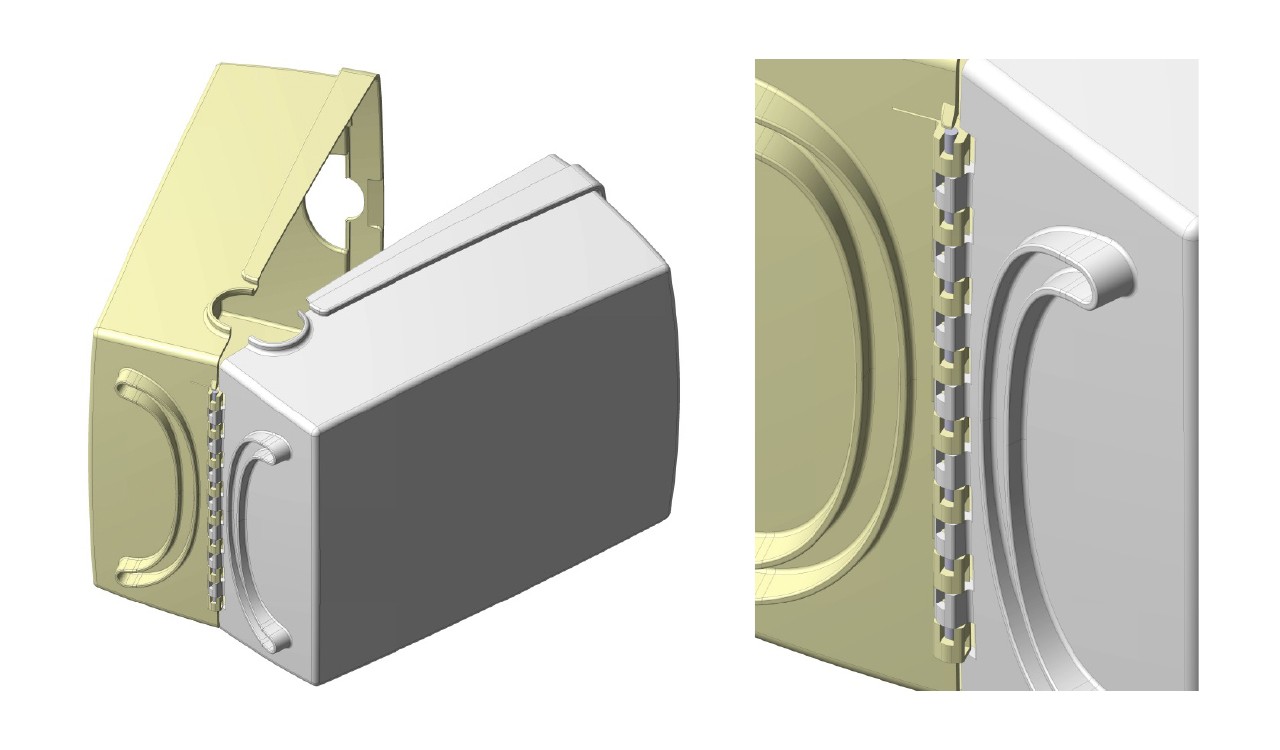

To realize the box we used a 1+1 figure equipment for the production of both valves of the container. Specifically, we used a type of mould called “reverse mould”, in which the injection and extraction system lies on the same side.

The plates containing the extraction system of the 2 steel figures 1.2738HH are driven by 2 hydraulic cylinders. Through a 1+1 injection point hot chamber injection system with filling nozzles, the material is injected directly into the center of by the 2 figures.

For both color variations (black and white), we then embellished the tactility of the surface and the aesthetic appearance through recife textures, directly obtained from the mold by photoengraving.

The mould has a footprint of 700 x 950 x 600 mm and a total weight of 2.000 kg, for the production of 2 shells that have maximum dimension, respectively, of 206 x 268 x 111 mm and 187 x 268 x 94 mm.

The project has been elaborated in 3D for every single component of the equipment with the software of which our internal technical office is equipped.

After that, out mould making workshop continued with the production of the equipment, with the help of CNC machines, milling machines and EDM and CAM system: construction took about 60 days.

Finally, the brand was created through digital printing, the technology that guaranteed us the best result in the material adopted, with countless possibilities of shapes and colors.

To make the box beautiful but sustainable, we chose to use an ABS with 50% recycled content guaranteed by the manufacturer of black color. Thanks to the high impact resistance and high dimensional stability, with this type of ABS can be obtained objects with a quality surface finish, for a wide range of applications and visible parts.

This version was also accompanied by a model of white color, where, however, the use of recycled material would compromise the value of the aesthetic performance, so it was preferred to use virgin ABS, limiting to certified production with reduced CO2 emission the “green license” of the product.

IlBox was recently presented at Vinitaly (Verona, 2-5 April 2023) with a success even higher than our customer’s expectations. Not only wine producers were interested in the container but also those who produce apple juice and extra virgin olive oil.

Thanks to its elegant, robust and versatile design, the box is suitable for use much more transversal than initially designed and this also thanks to the contribution of engineering, prototyping and industrialization provided by our Office “Design and Development” and the from the workshop and the stamping department that allowed the optimization of the final product