At first glance, some Project Managers and Responsible for the purchases would be tempted to answer quickly “no”: the fixed cost risk to be too high, making to increase the unit price of the finished piece.

But what if the quality of the component had a higher priority than the cost of production?

Then the answer changes, And it opens up a world of possibilities to design and develop together in a process of sharing and codesign that leads to innovative and ingenious solutions with cost-effective and profitable results in the medium to long term.

And this is where you recognize a business partner from a simple supplier: in the flexibility and dynamism of going beyond the obvious solution.

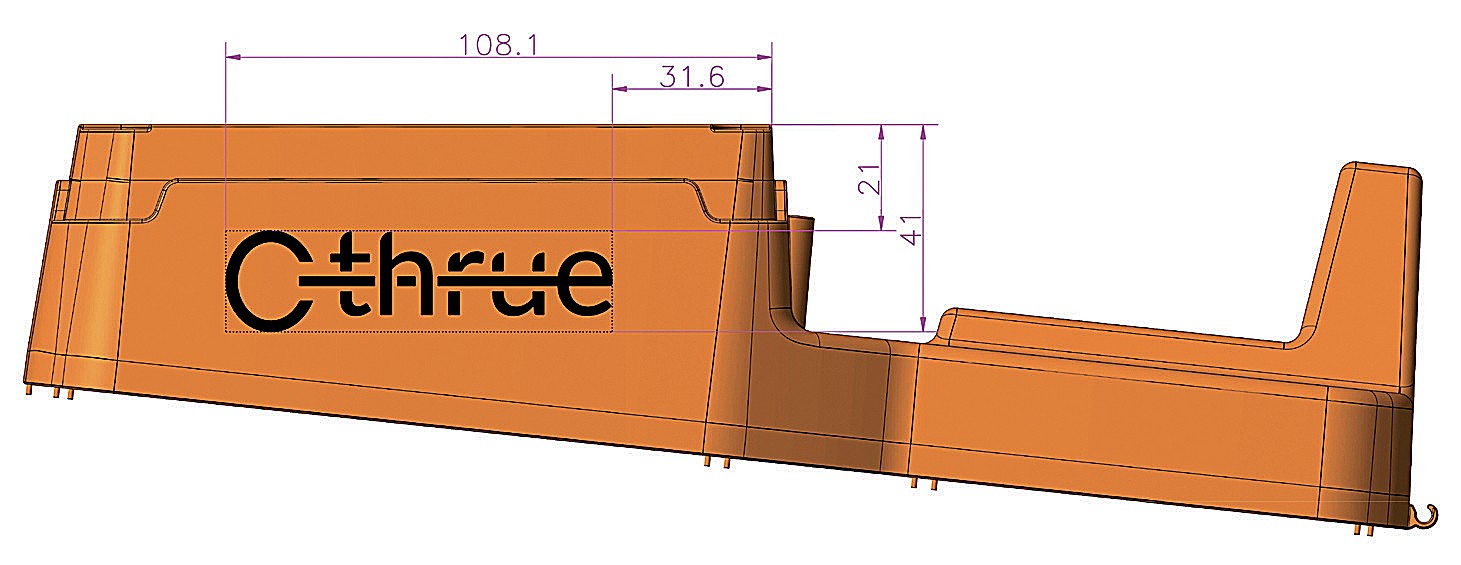

Take the case of C-thrue developed by IDS GeoRadar (Hexagon AB group) for which MPT has designed the housing and handle of the electronic components.

C-thrue is an all-in one Ground Penetrating Radar (GPR) designed for accurate scanning and real-time analysis of concrete structures. It allows to identify voids, post- and pre-tensioning cables, cavities, pipes and any other object inside the masonry before cutting or drilling the concrete.

C-thrue is slid over surfaces to scan. The product design and is plastic components had therefore to take into account some fundamentak requirements:

- have an ergonomic handle;

- be manageable;

- be as light as possible, but also robust and impact resistant;

- have an aesthetically pleasing design, like a kind of mini vehiclce.

IDS georadar, which had only an input on the design style and the dimension of the internal components, relied on MPT for an important co-design work during all phase of design and production.

- We have suggested the most suitable materials to meet the required requirements.

- We modified the mathematics to make the object injection moldable.

- We have optimized the molds needed to reduce costs.

With regard to the two half-shells, the MPT technicians suggested using a polyamide 6 50% filled with fibregalss, because the high thicknesses and the presence of reinforcing ribs required a techno polymer able to prevent various collapses, also highlighted by Mold flow analysis.