Injection molding of plastic articles

Every time,

perfect like the first time.

Concrete know-how in every phase of the design and manufacturing of thermoplastic components to provide efficient solutions and optimize every type of final product.

Experts in injection molding, versatile in customization

We call it HYPERTISE: HYBRID EXPERTISE

In over 50 years of activity MPT has acquired and consolidate experience in the different technologies of transformation and assembly of plastic materials, identifying for each order the optimal operating modalities to transfer on the production lines.

We offer the customer an almost total choice of customizations for any field of employment:

- Complex and varied geometries

- Wide range of colors, opaque and transparent

- Use of the most innovative raw materials and polymers

- Multi-cavity tools, two-component injection and gas-assisted molding

- Molding and pre-series tests

MPT Plastica guarantees the synergy between the designers of the technical office and the injection molding department technicians, who collaborate in every development phase to refine the process and optimize the result.

Whether it is car and motorcycle components, household appliances, industrial components and other sectors, through the Formula1Partner of MPT Plastica you can entrust to a single point of contact the entire processing flow, from design to molding, to logistics.

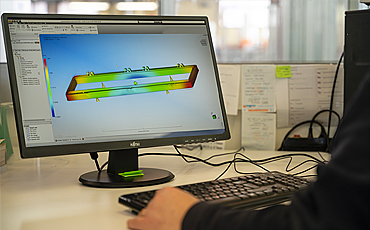

Moldflow analysis

To optimize the aesthetic-functional combination, the designers of our technical department perform FEM analysis, fluid dynamics simulations and Moldflow analysis to predict and prevent any molding problems and reduce waste.

With accurate data and a well-developed model, our simulation provide reliable and useful results to determine the best location of injection points, design appropriate power channels, identify the optimal speed and packing profiles to be imposed on the injection molding machine, evaluate the thickness distribution of the product and configure the cooling channels in order eliminate or minimize distortions and speed up the time-to-market performance of final products.

Choice of materials

The Research and Development department of MPT Plastica deals with testing new polymers and raw materials of the latest generation in order to identify new automated operating modes and transfer this knowledge on the production lines for an overall quality of the work increasingly high. We support the customers in the selection of plastic materials or innovative techno-polymers more suitable for the final use, ensuring objects with excellent technical and functional characteristics and compliance with international regulations.

Injection Molding Test

The expertise developed in the codesign and the synergy between the tools production workshop and the injection molding department allows us to provide a service of preliminary testing and high-performance molding testing.

Through the production of a pre-series of pieces, customers are able to evaluate concretely the finished product to meet the quality criteria required for series production.

Gas moldign and co-molding

Gas-assisted injection molding is one of the strengths of MPT Plastic. Thanks to this technique we are able to produce complex items and cables inside that cool quickly and at the same time guarantee strength and surface quality.

We also have a strong experience in the manufacture of molded products in bi-component engineering plastics (e.g. hard-soft or two-tone combinations) that meet higher quality standards in terms of aesthetics, touch and functionality without manual assembly operations. Our co-injection molding system speed up production times.

The MPT injection molding department has a central feeding and conveying system that guarantees excellent adhesion characteristics between the different components.

Smart Factory in progress

Since 2022, a completely digitalized and integrated system for managing warehouse flows, orders and supplies has been introduced, revolutionizing the entire traceability system, from raw material to finished product.

The objective is to optimize the entire logistic system according to the system of the FIFO (First In First Out) in order to assure an always more efficient service for our demanding customers in terms of:

- Automated inventory and customer lead time management

- Reduction of delivery times and human error

- Monitoring of information at every stage.

Injection Molding for all sectors

The MPT molding department covers a total area of 7,500 square meters and has a fleet of machines consisting of 24 presses, ultrasonic and vibration welding machines of the latest generation and 2 pad printing machines.

With an operating range of 65 to 2,300 tons, we are able to produce a wide range of plastic items in terms of material, lot, size and weight (up to 16 kg). We also provide multi-cavity tools and bi-components, with a strong point being gas-assisted molding.

The MPT molding department has a centralized feeding and transport system for the plastic material that allows the control of the dehumidification process necessary to guarantee high quality standards on the finished products.

In a department specifically dedicated to semi-finished products, different types of complementary processing are carried out, such as assembly and pad printing of finished products, according to the specifications required by the customer.

Motorcycle and scooter components

Automotive

Technical components

Appliance components

Household components