A PARTNER FOR OPTIMIZATION

The Twin automatic lubrication system was developed years ago, mainly for vehicles with many lubrication points, such as buses or trucks. Initially intended for road transport, it was subsequently adopted by major companies such as Caterpillar, Volvo and most recently by John Deere. Precisely in response to the needs of this latter customer, the customer undertook a project to optimize this grease pump, characterized by a body made of 30% glass fiber polyamide.

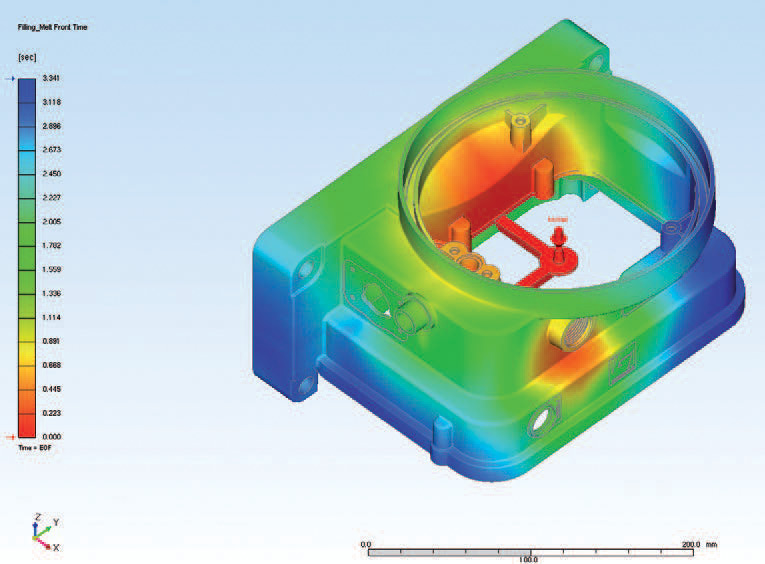

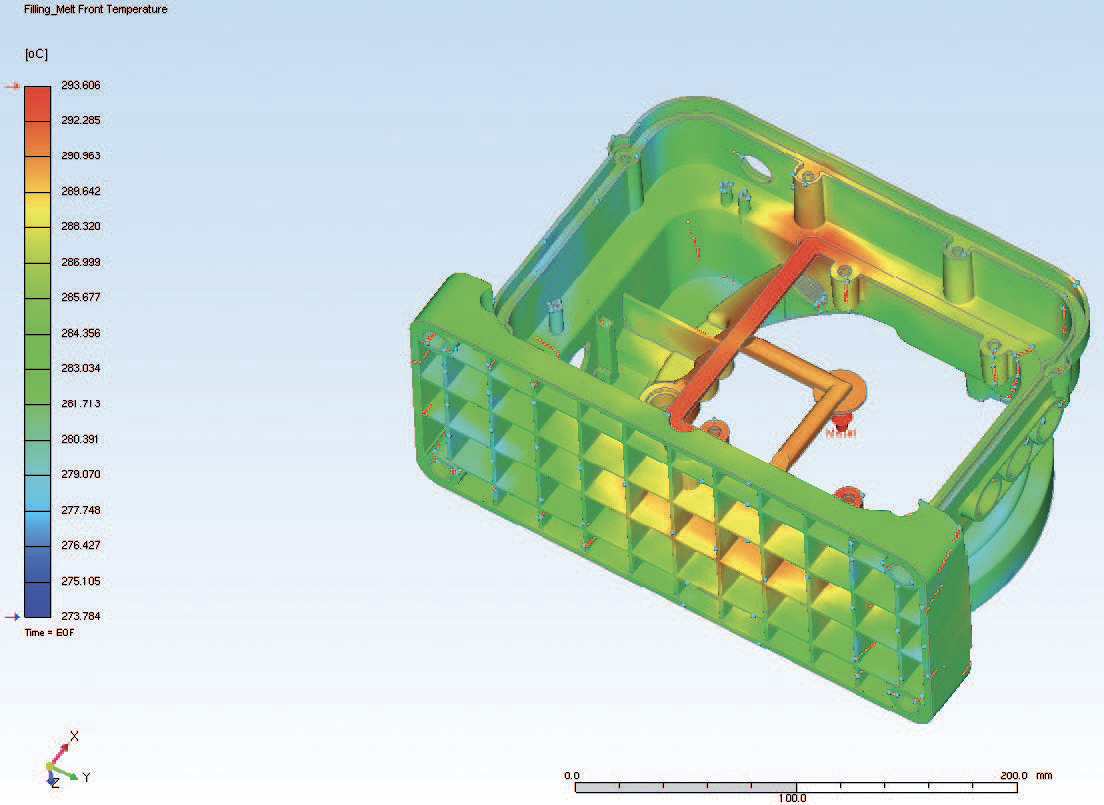

Initially, they moved from the original squared geometry to a cylindrical shape, which allowed to reduce overall dimensions and avoided the risk of the fat not being able to fill the corner areas and thus air pockets forming inside the container. However, some significant critical issues remained, mainly linked to sealing problems, the entry of air and water, deformations and shrinkage during the molding phase.

The customer knew well all the aspects relating to the functionality of the pump and the critical issues to be overcome, but they were completely ignorant of everything regarding the possible solutions obtainable through adequate molding of the plastic material. This is why we relied on MPT Plastica.