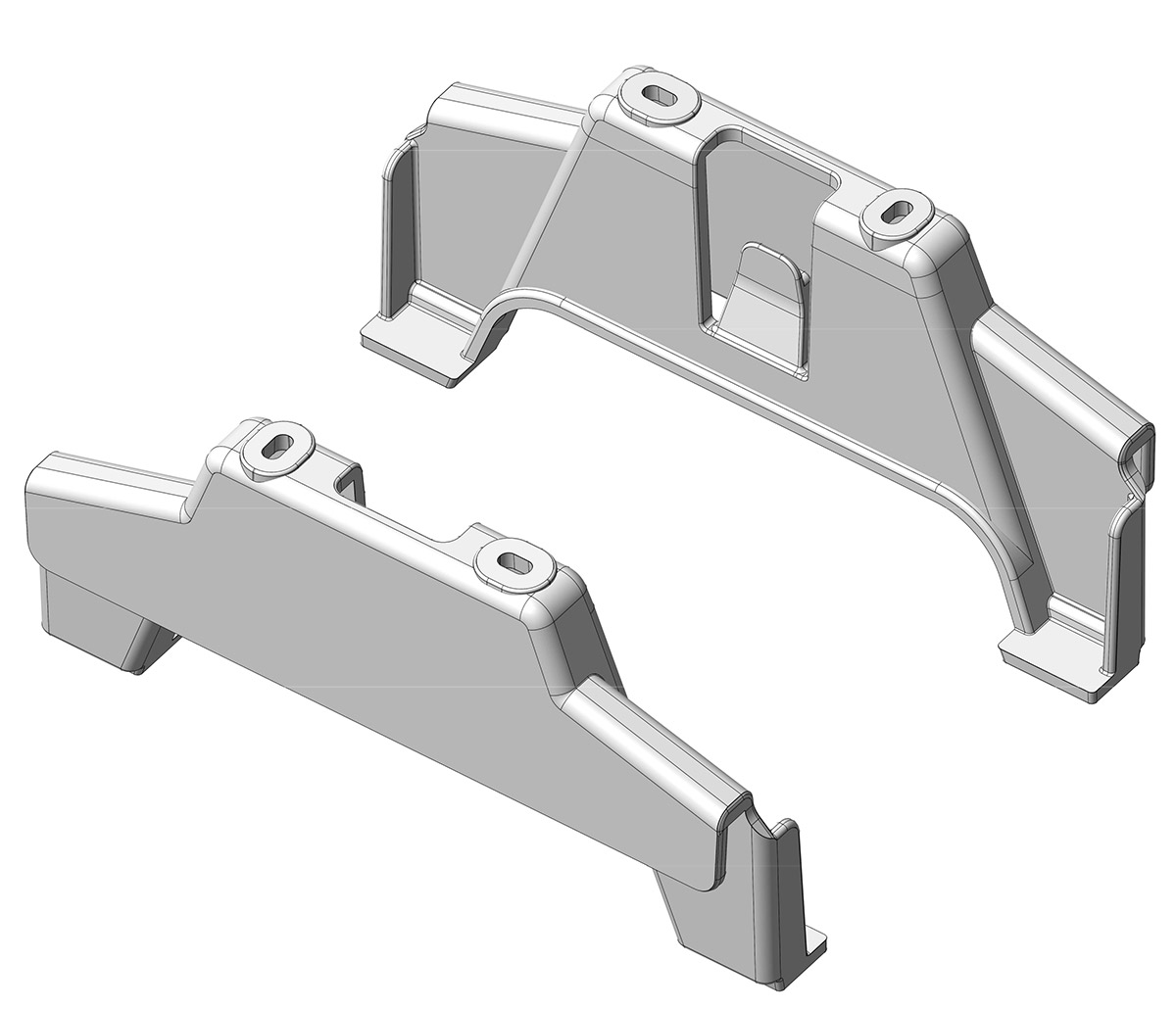

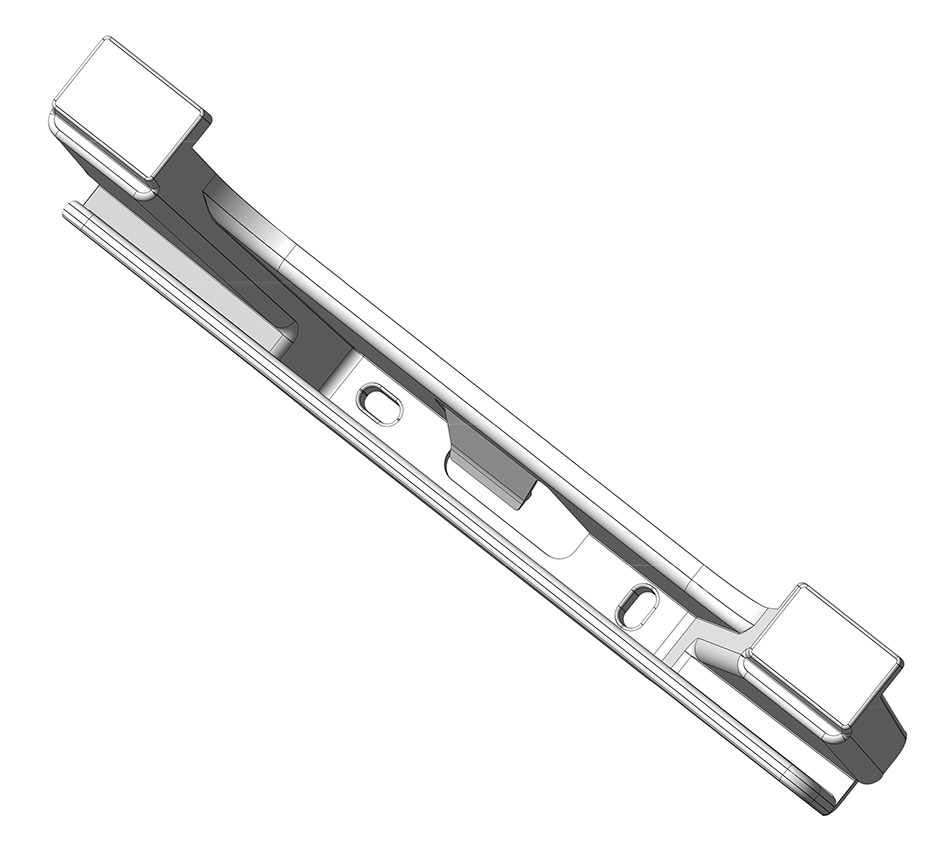

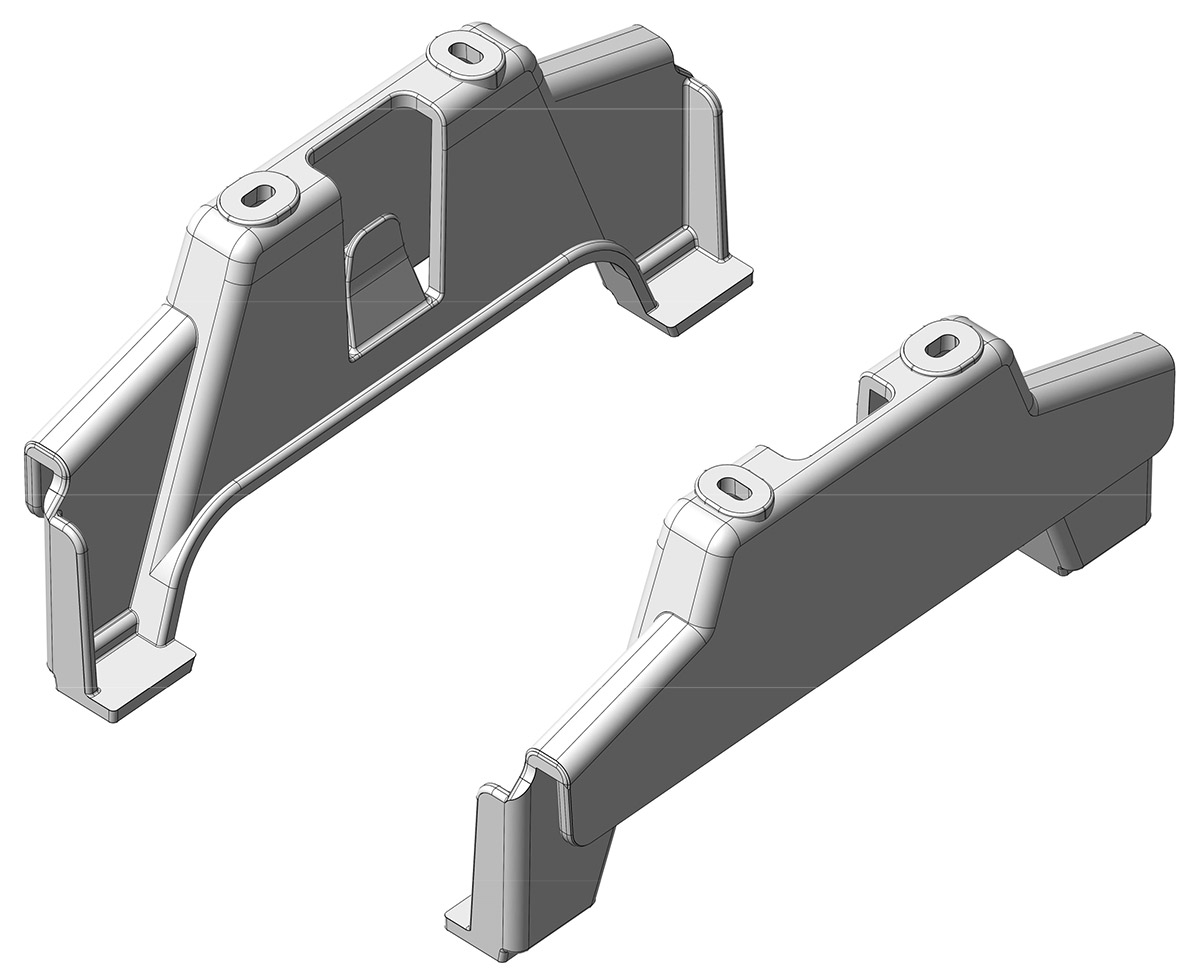

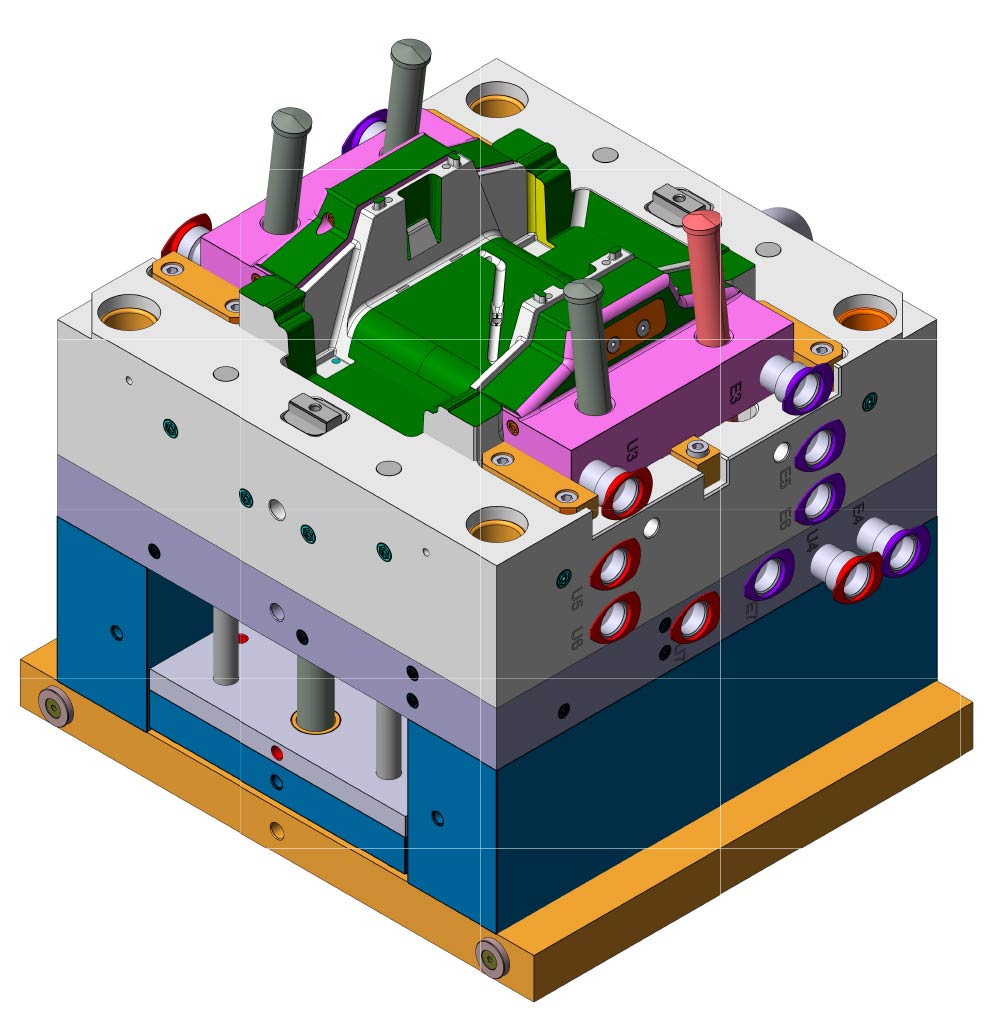

At MPT Plastica, we are constantly committed to providing innovative solutions that not only meet our customers’ needs but also exceed their expectations. A prime example of this approach is the project for the Sky Wifi Hub support. This product combines attractive design and practical functionality, ensuring stability and safety for the device.

In this article, we will explore the co-design and engineering process that led to the creation of the support base, highlighting the benefits obtained by the client and the lessons learned along the way.